Top 5 Ways Warehouse Automation is Transforming Modern Supply Chains

In today’s fast-paced logistics environment, efficiency and speed are crucial. Companies are under constant pressure to deliver faster, cut costs, and improve accuracy, all while handling increasing volumes. This is where warehouse automation becomes a game-changer.

From robotic systems to advanced data integration, automation is revolutionising how modern warehouses operate.

Know more about the top five ways warehouse automation is transforming supply chain management and how companies like ControlSoft Canada are leading the charge.

1. Real-Time Data Integration for Smarter Decision-Making

One of the most powerful aspects of warehouse automation is seamless data integration. By connecting RF scanners, RFID tags, and IoT devices directly to Warehouse Management Systems (WMS), warehouses can access real-time information about inventory, shipments, and order fulfilment.

Companies like ControlSoft Canada build end-to-end systems that feed production floor data into ERP, MES, or cloud platforms like AWS or Azure. This visibility allows managers to make faster, data-driven decisions, reducing delays and errors.

2. Reducing Labour Dependency & Human Errors

Manual warehouse processes often involve repetitive tasks that are prone to errors. Warehouse automation introduces AI-powered robotics and intelligent sorting systems that minimise human intervention while boosting productivity.

ControlSoft’s solutions are designed to automate these tasks, such as scanning, dimensioning, and package tracking, leading to fewer mistakes, faster processing times, and reduced operational costs.

3. Optimised Package Tracking & Sorting

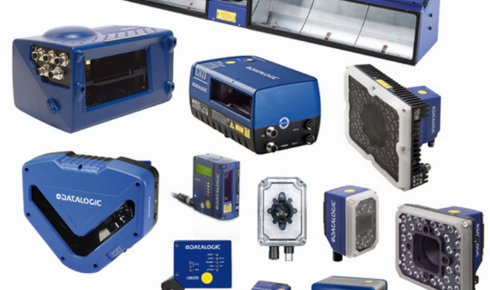

Using high-end stationary scanners from brands like DATALOGIC and SICK, ControlSoft enables real-time tracking of packages on conveyor systems. Integrated with backend systems like WHM or SAP, this allows for automated sorting and improved barcode verification.

Whether it’s capturing weight and dimensions using Cubiscan or directing packages to the right destination automatically, automation ensures accuracy and speed at scale.

4. Improved Scalability and Flexibility

As e-commerce and distribution demands fluctuate, warehouses must scale their operations quickly. Automation provides the flexibility to adapt to these changes without overhauling existing systems.

ControlSoft Canada offers customisable automation solutions that work for both small distribution centres and large fulfilment hubs, helping businesses stay agile and resilient in a volatile market.

5. Cost Savings & Competitive Advantage

Beyond efficiency, warehouse automation directly impacts a company’s bottom line. Reduced labour costs, minimised errors, and faster order processing mean significant savings over time.

Businesses that embrace automation today are positioning themselves for long-term success, improved customer satisfaction, and a stronger foothold in competitive markets.

Summary

Warehouse automation is no longer optional,it’s a necessity for companies that want to stay ahead in logistics and supply chain management. With industry leaders like ControlSoft Canada offering turnkey automation and data integration services, businesses can modernise their operations with confidence.

Looking to future-proof your warehouse?

Discover how ControlSoft Canada can help you automate smarter, operate faster, and grow stronger.